EMAIL ENQURIEIS

TALK TO NATIONAL STEEL DETAILING

GET IN TOUCH

SERVICES

Structural Steel Detailing

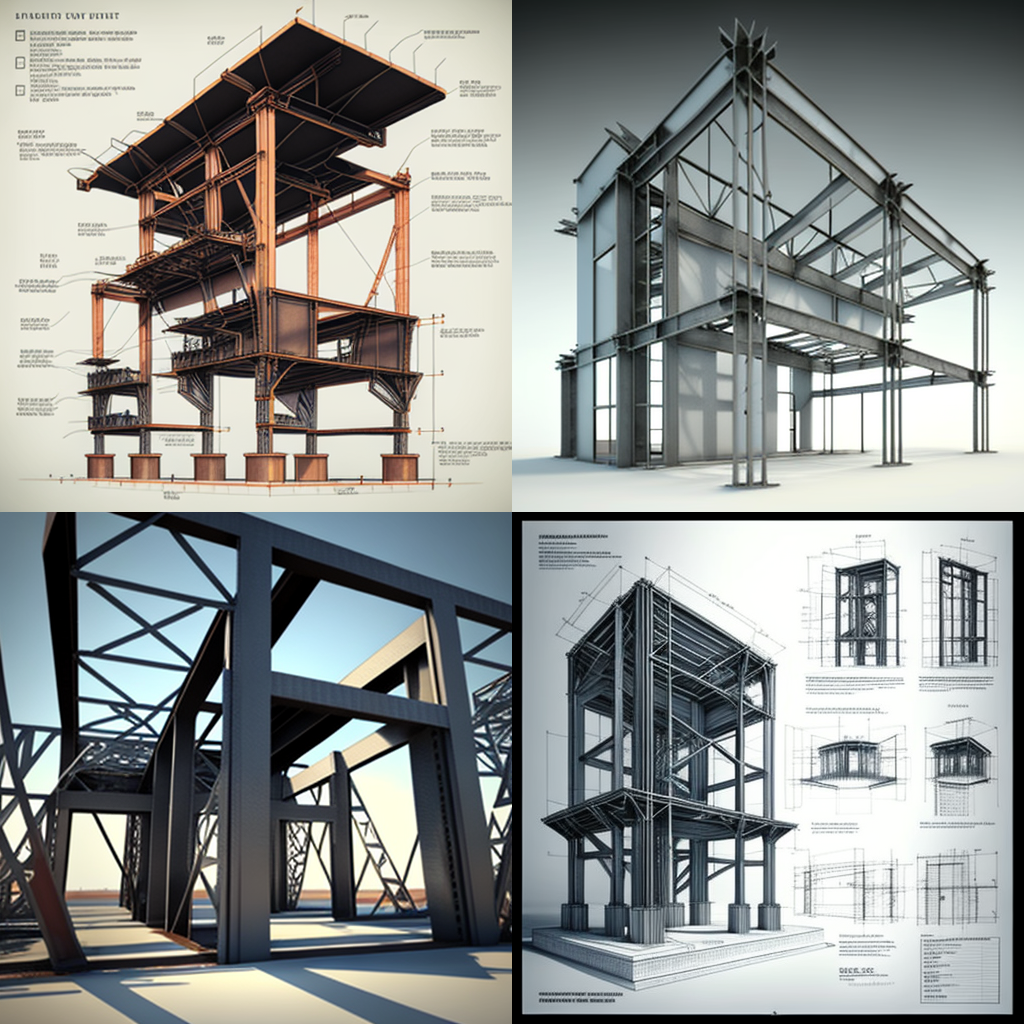

Our Structural Steel Detailing Services involves preparing the complete and accurate fabrication drawings for all structural steel elements of the structural frame that are shown and sized in the Structural Design Drawings.

The team at National Steel Detailing performs steel detailing by using the most advanced 3D structural steel detailing software, programs that give us the ability to pre-construct the steel frame in a virtual 3D environment. This allows us to get a complete 360 degree view of complicated framing connections and foresee potential conflicts.

Since the detail drawings are interactively tied to the model, this approach also gives us 100% connectivity of steel members. However, just like any other program, the quality of the output is only as good as the quality of the input. The real power of these programs is realised when we combine these tools with the extensive experience of our structural steel drafters.

Early Stages

Steel detailing is a multi-layered process in the construction industry. To begin with, the structural engineer or architect will suggest an idea for a project, and give a standard description on paper. The drawing they create could be linked to mechanical systems which relates to steel members and their fabrication. The steel detailer will take these initial drawings and turn them into detailed and accurate diagrams for every single steel piece. These plans and drawings could refer to the making of steel members such as trusses, beams, braces, columns and joists.

Shop Drawings

These detailed and accurate drawings produced by the steel detailers are known as shop drawings, and they indicate the exact specification for fabricating each member of a structure during structural steel detailing. Comprehensive shop drawings for structural steel detailing typically involve several elements, such as size, required dimensions, material description, preparing surfaces, welding, painting and manufacturing conventions.

Erection Drawings

The steel fabricator produces structural steel members based on the detailer’s shop drawings. The steel detailer will then step in to produce erection drawings for the steel members in the field. These drawings will be referred to by the steel erector so that they know where to build with the steel pieces. In the erection drawings, the detailer will include dimensional plans to identify the steel members in addition to any other work needed on the site, including bolting, welding and installing masonry anchors.

Techniques Used

Structural steel detailing has utilised the latest technology to produce incredibly professional and meticulous designs. Beforehand, structural steel detailing was completed on paper, using pencils, rulers and triangles. Today, steel detailers use Computer-Aided Design (CAD), which is a software that allows designing in 2D. It has dramatically changed the industry, making things much more efficient and faster while also more cost-effective. Most companies now use 3D CAD, in which the model has an additional z-axis, allowing diagrams to be created in 3D. With this computer software, projects can easily be scheduled and tracked, creating a high degree of output with very high accuracy.

Additional Tasks

As well as completing the above tasks, the steel detailer usually has other responsibilities, which may include having to show drawings to the structural engineer before they are released to the fabricator to be evaluated. They also have to observe parameters of design drawing and make sure they comply with industry standards. To check the accuracy of their design, the structural steel detailer should send their drawing to another steel detailer. If there are cases where there is insufficient information about structural drawings, they may offer links subject to the structural engineer’s sanction. Finally, it is essential that they resolve any complaints or comments that may have come out of the approval process.

Architectural Steel Detailing

Our Architectural Steel Detailing Services involves complete and precise fabrication and erection drawings of custom architectural products.

With stairs being an exception, these items often have minimal design loads that don’t effect the structural frame and often include; stairs, handrail, guardrail, ladders, bollards, gates, equipment support framing, and catwalks. Also included in our architectural steel detailing services are all erection plans, elevations, sections and details for the proper and safe installation of the structural steel.

The talented team at National Steel Detailing usually uses their own internally developed set of blocks, sections, and details to detail most architectural elements in architectural steel detailing.

Architectural steel detailing is the drafting of items such as balconies, balustrade and staircases. The goal is to create a selection of fabrication drawings a fabricator can work with. Structural Engineers produce drawings stating the sizes and forces, whereas architects produce drawings displaying the layout and design intent.

We use the information from the structural engineers drawings in conjunction with the architects drawings to produce:

General Assembly Drawings displaying the detailed design

Assembly drawings depicting how each section is welded

Single Part drawings portraying how to cut and drill each plate, section etc.

Further we include in every fabrication pack:

Material & bolt lists

NC files (which are used by the stockholder to pre-cut and punch the structural steel sections)

DXF files (for laser cutting all the plates)

Architectural steel detailing is the process of drafting items such as staircases, balconies and balustrades. While structural engineers create drawings that show the forces and sizes of a project, architectural drawings are more focused on displaying the design purpose and layout of a project. It’s this reason that the main goal of architectural steel detailing drawings is to produce an image that a fabricator can easily work with and follow.

It’s the responsibility of the architect to make sure a project complies with the functional and design requirements of a project, as this provides an essential base that a structural engineer and fabricator can use to develop a project, ensuring it is functional and safe.

Fabrication Support

National Steel Detailing provides a full selection of Fabricator and Erector Support Services to ensure the fabrication and erection process goes as efficiently and easily as possible. These fabrication support services include preparing complete and precise reports, CNC files, and material interchange files for the shop and field. The majority of this information is exported directly from the 3D Model to ensure 100% coordination with the the fabrication drawings.

What is CNC?

If you’re a maker, tinkerer, or 3D printer, you’ve probably heard the term “CNC” used a lot. It stands for computer numerical control, which is a process used to manage many types of traditional machining tools as well as newer additive manufacturing machines like 3D printers. This process is what many organisations use for fabrication support in the construction industry.

The first machining tools, such as mills and lathes, were controlled manually by turning dials and moving levers while periodically checking work manually. In contrast, the CNC process automates the machine movements and actions using a computer that delivers instructions to the CNC machine, which is extremely helpful for fabrication support.

As well as automation, CNC enables you to fabricate complex parts through the precise control of tools. Therefore, CNC can be applied to a variety of machines and is independent of the machine’s function, be it cutting, printing, or something else.

MEP Detailing

National Steel Detailing's goal is to assist MEP contractors and engineers maximise efficiency by creating the fastest and safest path to integrated construction processes, something called MEP Detailing.

Our team specialises in MEP Detailing, offering the implementation and delivery of advanced and proven concepts to achieve far more accurate planning and management of your project.

Mechanical, electrical and plumbing (MEP) shop drawings are essential to most construction jobs, be it big or small. Our MEP detailing and MEP shop drawing services are a crucial part of the construction process and include not only mechanical, electrical and plumbing work but also HVAC, ductwork, sheet metal drawings, and piping. For smoother fabrication and quicker insertion, MEP detailing and MEP shop drawings will enable contractors to complete the job regardless of how complex it looks on the surface.

What is MEP?

MEP is an acronym that stands for mechanical, electrical and plumbing engineering. These three technical disciplines perfectly describe the systems that make building interiors suitable for human occupancy. MEP installations are addressed together due to the high degree of interaction between them, and also to prevent conflicts in equipment locations, which has become a common problem when electrical, mechanical and plumbing systems are designed in isolation.

STEEL DRAWINGS

What can I hope to achieve with steel shop drawings?

Accuracy

Steel shop drawings are detailed diagrams of a range of components that you need in your building. For instance, every building or plant needs doors, windows, Mechanical, Electrical & Plumbing Units (MEP), Air-conditioning units and so on. All of these components can’t be designed when construction documents are drafted. However with detailed steel shop drawings, suppliers, manufacturers, builders and contractors get accurate information to fabricate and install steel members and other components adequately.

Bifurcation into two subsets for convenient fabrication and installation

Detailed steel drawings are made up of two individual drawing sets. The first is shop drawing detail and the second is erection drawing detail.

Shop steel drawings explain details that are needed for manufacturing steel components, whereas erection drawings are used to facilitate the installation of these components on the actual construction site.

Framing Plan helps in building the foundation for steel components

A framing plan typically accompanies detailed steel drawings. It depicts information relating to the number of beams and columns required for framing the structure of steel components. This information is crucial because it helps determine angles, holes for drilling, plate positioning and length besides a horde of other useful things.

Fabrication drawing standards are ensured

“A picture is worth a thousand words”, and if you didn’t already believe this, you better start now. Every single person who has ever worked on a construction project will tell you this, industry standards are damn essential to adhere to.

STEEL DRAFTING SERVICES

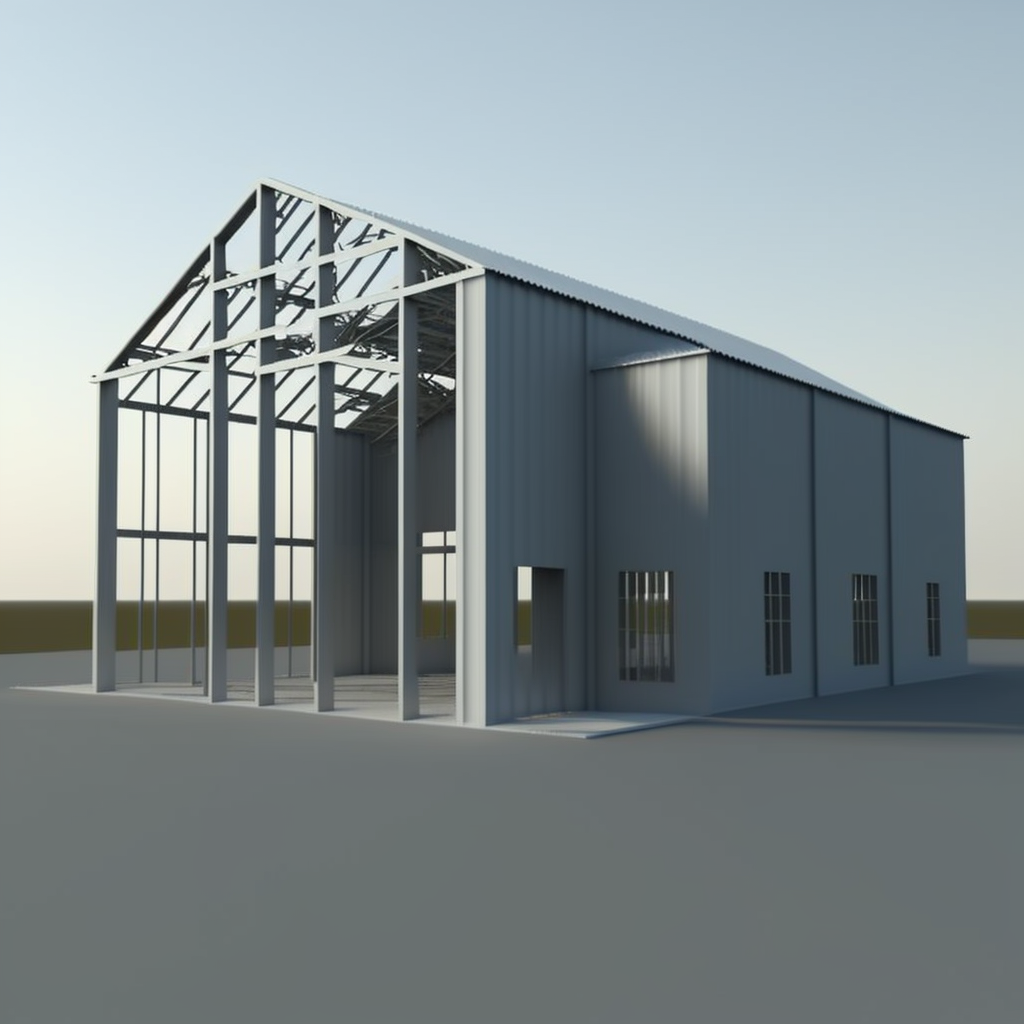

Before any structure can be created, appropriate and adequate planning has to happen first with steel drafting. By doing so, the quality of the structure, regardless of the material used can be determined. As with anything else, proper planning means putting what the structure should be like into writing. Included in these writings are the materials to be used and the dimensions of each of the part.

In order for someone to understand how a structure is formed, a deep understanding of steel detailing is crucial. That being the case, you first have to understand that steel detailing is the term used in order to describe the creation of blueprints. In most cases, steel detailing is also referred to as structural steel drafting. In this process, the blueprint for the structure is prepared usually by a draftsman.

Structural steel drafting usually involves the creation of two sets of drawings. The first drawing is generally used by the steel fabricators, and includes details on what materials should be used for each part as well as the dimensions. The second drawing in steel drafting is typically meant for the steel erectors. This drawing usually includes details on how each of the steel structure is to be assembled and put into place.

Detailed steel drafting is usually done when the engineers and the architects receive a new project. To come up with the draft, the engineers and architects would have to consult with local government units to understand what the different requirements are for the construction. All the information would then be passed on to the draftsman who would start preparing the drawings for steel drafting. Construction companies as well as clients would oftentimes take advantage of tilt up panel detailing especially if they are on a tight budget.

Information and details indicated in a steel drafting draft usually varies for each project, especially if the project would involve the use of tilt up panel detailing. This is because tilt up construction makes use of casting slabs and surfaces that have been allowed to cure. Very few changes in details are made, and all the items are constructed to easily fit each other like lego. This, of course, would also mean that there is very little need for a CAD software when coming up with the designs. However, if the traditional construction process would be used, CAD would tend to be in prominent use as it would make it easier for the draftsman to come up with the needed designs. Some structures would also make use of BIM as this software would also make it possible for the engineers and architects to input as much detail as possible.

SHOP DRAWINGS

While construction drawings relate more to the building or structure as a whole, shop drawings are for various building components.

Shop drawings are a number of drawings that give the details of various components that help in the construction of a project. Shop drawings are typically prepared by your contractors and material suppliers.

Both construction drawings and shop drawings are done before the real construction begins. While construction documentation includes building design and revisions that have taken place since the beginning of the project, shop drawings depict how the building was originally designed internally, with MEP components with their exact dimensions mentioned. A step-wise formation manual of your construction process, if you will.

Shop drawings compliment working drawings, so think of them as an add-on or a detailed development of construction working drawings. They usually display fabrication and installation details, structural steel detailing, windows and door installations and other MEP components. With the assistance of shop drawings, you’ll be able to understand the kind of materials you will require for the components, the dimensions of the proposed installations, and the timelines. Getting shop drawings designed should be very high on your to-do list before your project begins.

Based on the kind of project, the type of property, and your budget, your shop drawings will have varied electrical drawings, mechanical drawings and plumbing drawings.

The following list include essential details that your shop drawings must include:

The date of the original issue

The date of all revisions

The title of the project

Project number

Names of the contractor, subcontractor, manufacturer, supplier and separate detailer, wherever applicable and necessary

Order of sequence and sequence number for each drawing

Identification of all materials and products with their dimensions

Relation of various components to adjacent materials and structures

Applicable building standards

All you need to know about structural detailing

Structural steel detailing is a drafting process which assists the fabrication of hot and cold rolled steel. The structural detailing process involves producing detailed drawings for contractors and fabricators, which is very important as it provides an essential link between professionals such as architects, engineers, fabricators and contractors. Structural steel detailing is primarily used in the construction and development of bridges, buildings, non-building structures and industrial plans. National Steel Detailing provides these services with efficiency, accuracy, professionalism and care.

Structural steel detailing is part engineering and part architecture and requires the expertise of both industries. From an architect’s perspective, the design and appearance of the future structure is highly thought about and considered. From an engineer’s perspective, the calculations are defined to make sure the building is strong, safe, and correct. Structural detailing needs both perspectives when creating drawings that feature accurate dimensions for every part of the framework. This precision is crucial as these are the measurements welders and builders will use.

Structural steel detailing is an exact science, meaning there’s no room for mistakes or miscalculations. This is why it’s very important to choose a skilled detailer with a pretty much perfect reputation. However, there’s more to it than just finding a structural steel detailer who’s good with calculations and has an eye for design. They need to be experts on local regulations and guidelines and know everything from minimum bearing limits to OSHA standards. It’s also a structural steel detailer’s responsibility to make a complex project as easy and smooth as possible for building teams.

Since this part of the structural detailing process happens in the early stages of planning, there’s simply no room for mistakes when it comes to structural steel detailing. Accuracy is key, and that’s exactly what National Steel Detailing ensures. Our structural steel detailers ensure that clients and colleagues enjoy only the best construction from planning and ordering materials to steel fabrication and erection.

All guidelines of construction must be part of your detailer’s knowledge, from any state to any city requirements. This means structural steel detailers have to keep up with AISC and other common national standard practices. Even though the project may come across as very small or simple, it still requires exact measurements and the expertise that only a highly skilled structural detailing firm can provide. So don’t settle for less, and choose National Steel Detailing in Sydney.

Structural steel detailing is a significantly important process dealing with the construction of steel members like buildings, bridges, elevators, air-handling units and also other non-building components. The structural engineer turns ideas into designs onto paper, which involves the creation of structural drawings. These drawings are submitted to a detailer who create meticulous diagrams for the erection of steel members like columns, beams, trusses, stairs, and handrails. These diagrams are called ‘shop drawings’. For steel members, they are also known as ‘structural steel fabrication drawings’.

Structural Steel Detailing Responsibilities:

A detailer must follow a set of duties to be performed during the detailing process:

Follow design parameters and industrial standards while generating drawings

Submit the detailed diagrams to an engineer or architect before fabrication begins for proper evaluation.

To send RFI or request for information to the concerned member, if he is not sure of any information pertaining to the project.

Submit the prepared diagrams to a person who is responsible for correcting or making it accurate ( generally called ‘checker’).

Monitor and resolve any changes made after correction.

Technology used in Structural Steel Detailing:

Computer-aided design or CAD is the technology used for steel detailing. Earlier, manual drafting methods were used.

3D modeling is the technique used for steel detailing which is an advanced version of 2D drafting. 3D provides a better visualization and insight into the project.

3D modeling can be done with software like X-Steel, AutoCAD, and Microstation.

WHY CHOOSE NATIONAL STEEL DETAILING

AUSTRALIAN OWNED AND RUN

National Steel Detailing is proudly Australian owned and run. Our design manager Nick Selby has been managing drawing offices and producing high quality shop drawings in Australia since 2012. National Steel Detailing is always striving to constantly improve our systems and processes by utilising the latest steel detailing software (Tekla and Inventor), purely to give you exceptional service that’ll ensure quality outcomes for your projects. National Steel Detailing is primarily based in Sydney, but more specifically, the Sutherland Shire. Our Sydney services range from detailed drawings, steel drawings, steel drafting, steel detailing and more!

PROFESSIONAL SERVICE

National Steel Detailing prides ourself on the most professional service you could ever come across. Our clients and companies we work with continually rave about the professionalism of our structural steel detailing services, because at the end of the day, you are our number one priority. National Steel Detailing perform a host of services in Sydney and the Sutherland Shire, including detailed drawings, steel drawings, steel detailing, structural steel detailing, steel drafting and more. Even though National Steel Detailing offers a range of services, we ensure each and every one is carried out with the most professional service.

FAST PROJECT TURNAROUND

Something unique and special about National Steel Detailing is our fast project turnaround. National Steel Detailing is a company that values your time, so we understand just how important it is to get your projects completed as quickly and efficiently as possible. Whether you’re wanting our detailed drawings, steel drawings, steel detailing, structural steel detailing, or steel drafting services, National Steel Detailing will always strive to have a fast project turnaround. Even if the Sydney project is enormous or minuscule, we’ll make sure not to keep you waiting.

IS STEEL THE MOST DURABLE OPTION FOR YOUR NEXT STEEL DETAILING PROJECT?

Steel is a metal that is quickly becoming an essential and favoured construction material of residential and commercial builders alike. There are several benefits of steel, which has led to its popularity in the construction industry and the profession of steel detailing. National Steel Detailing is a strong believer in steel and is happy to share it’s benefits from our decades of experience in steel detailing.

Steel Is Very Durable

Durability is one of steel’s greatest features for many reasons. Firstly, it can endure strong weather conditions such as hurricanes, high winds and even earthquakes - the perfect material to use in steel detailing. Steel frame housing components have the impressive benefit of fire resistance, able to withstand temperatures of more than 1000°C, meaning the structural quality of steel frame building would remain even after a bush fire, which is a convenient and reliable feature to have. Steel is more than just fire resistant. It’s also resistant to termites, creeping, cracks, splitting and rotting, essentially all the weaknesses of wood, which is exactly what steel detailing projects need. Steel is classified as having long-life durability as it doesn’t age or decay nearly as quick as other construction materials, meaning steel lasts longer before refurbishment is required. If building extensions or renovations are made, steel is inherently adaptable and flexible enough to handle it with little disruption, something that comes in handy for steel detailing.

Steel Resists Corrosion

Steel is made with carbon and it’s heated so that it can bond, so it is very hard and very resistant to corrosion which makes it perfect for outdoor buildings and structures that are going to be exposed to elements that may cause corrosion and other damage to metals that are not as tough as steel. It’s for this reason that makes steel perfect for steel detailing. Since steel is resistant to corrosion, so it’s the perfect siding or structure material for buildings when steel detailing.

Steel Is Termite Resistant

Termites create a significant risk for many structures, especially those made of wood. Steel framing is not vulnerable to termites since it doesn’t offer a food source for them, so that risk isn’t a concern for steel detailing profects. Also, steel structures don’t need termite treatment, making it not only durable material but a cost-effective one.

Steel Is Mould Resistant

Steel doesn’t provide a food source for mould to grow and is a much more suitable structural material than other materials such as wood. Steel framing in steel detailing can also avoid the onset and growth of mould through its dimensionally straight and mechanically connected framing members. More so, steels moisture and leak resistance makes structures stronger and more resilient for an extremely long period of time, which makes steel detailing much easier.

Steel Is Dimensionally Stable

Dimensional stability is a main concern when building a structure, so it’s essential to select a material which does not shrink or swell with changes in moisture content and humidity, which commonly occurs in structures that are made with wood or bricks. Steel does not expand or contract with moisture content and will not warp, split or crack. More so, steel is isotropic, meaning it has the same dimensional properties in all directions. Unlike other materials such as wood, there is no grain, meaning the strength of steel will be the same in all directions, making it a quality material that remains stable.

Steel Is Reliable Strength

Alloyed metals have the strength of the metals or alloys that are used to create them, meaning that steel has both the strength of iron, a metal that has long been used for weapons, structures, and more, in addition to the strength of carbon. This also means that the resulting alloy is going to be stronger and more durable than both of its parts. Superheating the metal in the bonding process helps to temper or strengthen the steel so that it’s even stronger than when you first started, meaning that this is going to be a very strong metal that is going to last and that is going to help keep the integrity and strength of your structure for decades.

WHAT IS TEKLA AND HOW DO WE USE IT?

When it comes to steel drawings and steel detailing, our extraordinary and professional team at National Steel Detailing depend heavily on the soundness of the software to get the job done correctly. That is why we use only the prime and latest versions of model-based software on the market. One of our favourite brands of software is Tekla, because it offers many benefits to our clients, not to mention our engineering team, and makes everything run extraordinarily smoother in the structural steel detailing process.

Tekla Structures is utilised in the construction field for concrete and structural steel detailing, precast and cast in-situ. The software enables users to create and manage 3D structural models in concrete or steel, and guides them through the process from concept to fabrication. The process of shop drawing creation is automated.

Here are some of the leading benefits we have discovered using Tekla Building Information Modelling (BIM) software in our NSW-based office:

2D drawings and 3D models created with Tekla are accurate and meet our clients’ needs perfectly

The software allows us to build even the most complex of structures with relative ease

Tekla is very versatile, and there is a seemingly infinite amount of structures that we can model in the system

Our team can incorporate high detailed information thanks to the flexibility of the BIM software

The open system approach provides much flexibility and connects smoothly with other interfaces including analysis and design packages, and spreadsheets

Tekla offers a one-size-fits-all approach whether we are dealing directly with the steel fabricator or the manufacturer

The software gives us plenty of options and capabilities, and we can model a broad range of materials including concrete, wood and steel

Tekla supports a number of formats including SNDF and IFC

It assists us improve our productivity and ultimately our profitability

Efficient designs and constructability are realistic, meeting our clients’ high expectations

The software allows us to undertake amendments and additions with ease ensuring change management is handled effectively and professionally

It assists us with a wide range of services including structural analysis, design and steel detailing

Tekla is perfect for complex building projects or smaller residential plans

It was created and developed by structural engineers for structural engineers who have a thorough understanding of the building industry and the intricacies involved

Tekla improves construction quality with tools such as 3D views and live schedules

Tekla offers material cost estimates to help us efficiently manage labour and other expenses

WHAT IS INVENTOR AND HOW DO WE USE IT?

Work with a complete set of steel design and engineering tools

Inventor® CAD software provides professional-grade 3D mechanical design, documentation and product simulation tools. It enables you to work efficiently and smoothly with a strong mix of parametric, direct, freeform and rules-based design capabilities, an ideal software when undertaking a structural steel detailing project.

Share timely feedback with built-in collaboration tools during steel detailing projects

You can work with anyone, anywhere, regardless what CAD software they use.

Use cloud-based design reviews to gather feedback from key stakeholders, regardless where they are

Follow the entire product development lifecycle with one data model

Satisfy demands for customised products and automated processes for steel detailing projects

Enable fast assembly reconfigurations powered by iLogic.

Design efficiently using specialised tools for sheet metal and frame design.

Choose standard components from a customisable content library for bolted connections, gears, cams and more.

Mechanical design and 3D CAD software

Use Inventor® 3D CAD modelling software for product and mechanical design when undertaking projects like structural steel detailing.

National Steel Detailing specialises in the production of steel workshop drawings used by steel fabricators and manufacturers. We provide fast and accurate structural drafting services with error-free solutions. If you’d like to know more about us and our services feel free to reach out! You can do so by simply clicking on this link and filling out a contact form!

RECENT NEWS POSTS

TESTIMONIALS

“We have been fortunate to work with National Steel Detailing on multiple projects in the past 4 years. Some really challenging builds have been made easier due to the knowledge, experience and engineering details from National Steel Detailing. We look forward to continuing working together.”

MATT CHAPMAN, MATTBUILD

“National Steel have handled a wide variety of projects for us over the last 6 months, they have made the detailing of projects seamless as as stress free as possible. Their expertise, patience, and advice are very much appreciated. It is a pleasure doing business with Nick and I wouldn’t hesitate to recommend him.”