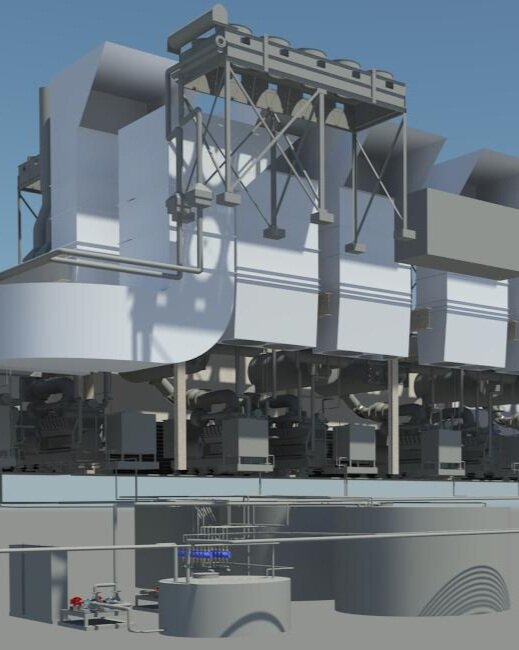

NATIONAL STEEL DETAILING’S Shop Drawings give those on site a clear, precise picture of the construction process. Surveyors, engineers, builders, trades and any others involved, can clearly see the process and task ahead. Our shop drawings are accurate, detailed, and can be delivered quickly.

What are shop drawings?

If you’re involved in any kind of building project, you’ve most likely heard of shop drawings. These detailed diagrams play a vital role in the design and manufacture of quality components, providing a concise way for architects, engineers, installers, and fabrication shops to communicate and coordinate with each other.

Shop drawings are a set of drawings that communicate the details of each component in a construction project, typically prepared by your contractors and suppliers. While construction documentation includes building design and revisions that have taken place since the beginning of the project, shop drawings depict how the building was originally designed internally, with MEP components with their exact dimensions mentioned.

Shop drawings supplement working drawings. Consider them an add-on or a detailed development of construction working drawings. They typically include fabrication and installation details, structural steel detailing, windows and door installations and other MEP components.

With the help of shop drawings, you will be able to figure out the kind of materials you will require for the components, the dimensions of the proposed installations, and the timelines.

What is included in a shop drawing?

Shop drawings depict the stage of the prefabrication process after drafting design drawings and specifications. They include more detailed information than design and construction drawings and focus on the particulars of a prefabricated component.

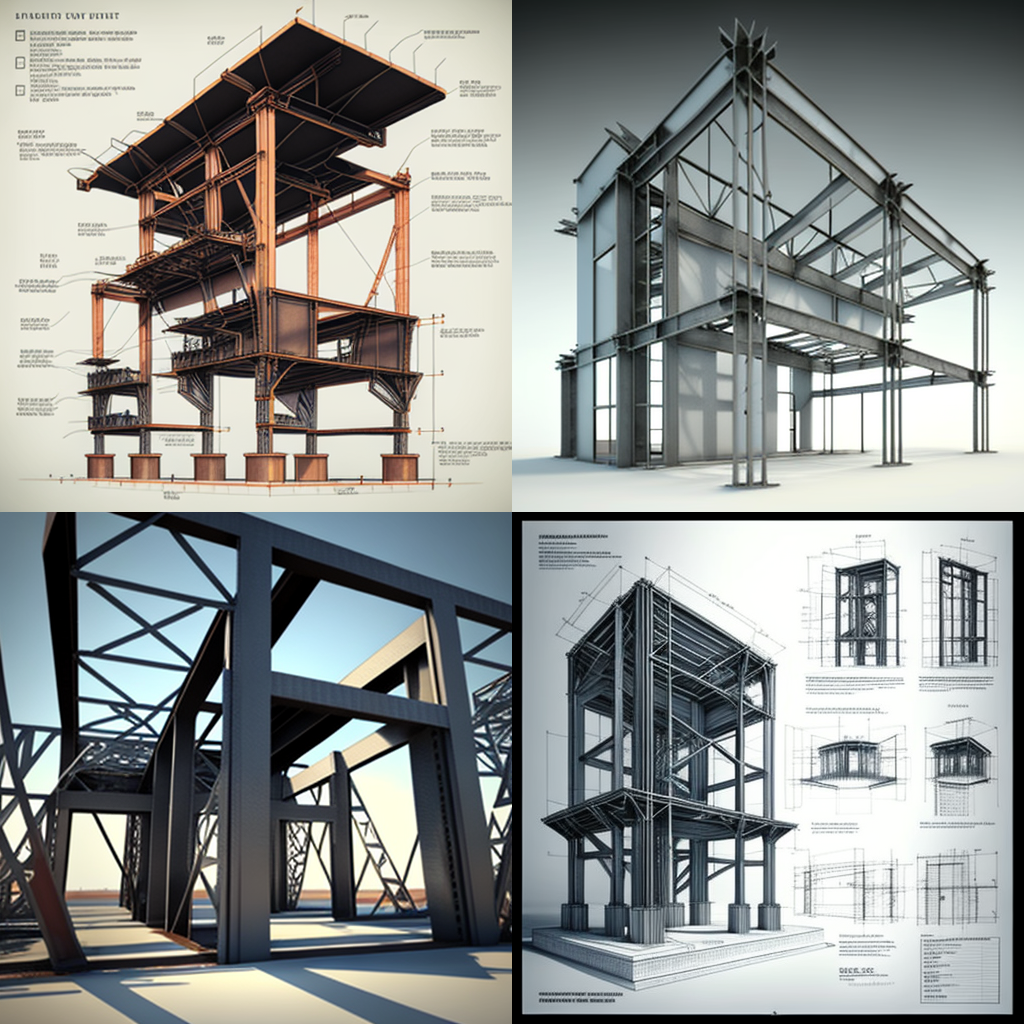

A shop drawing typically contains:

The project title and number

The date of the initial drawing, as well as the dates of subsequent revisions

Detailed CAD drawings of the prefabricated component, often shown from different angles

Information required to fabricate the component, including physical dimensions, material specifications, manufacturing protocols, and special instructions

Information required to assemble or install the component, such as step-by-step instructions, a diagram of connections, and a list of supporting materials that must be procured and prepared for successful installation

Detailed references that describe how the prefabrication design addresses the specifications and requirements of the original design and construction documents

Notes of any changes or variance from the original design and construction documents

Notes of any key dimensions at the job site that must be checked and verified before the component can be fabricated and installed

When submitted to a design team for review, shop drawings are usually accompanied by samples. The samples represent a selection of fabrication materials that require approval, based on the preferred colour, texture, finish, and appearance.

Why are shop drawings so important?

Shop drawings are an integral component of the Construction Document Submittal Process, which is required for all large construction and restoration projects. The architect and engineer needs submittals to verify that the correct products, methods and services are being utilised on a project. Submittals are based on requirements documented in the Construction Specifications. Submittals aren’t for architects or engineers to change their specification requirements, but rather to confirm that their specified products, materials, colours, services, and finishes are complied with from the several suppliers and subcontractors on a job. Once the shop drawings are approved in the submittal process, they become part of the contract record and the foundation for what the architect and engineer will accept upon delivery and installation on the job.

The VALUE of shop drawings

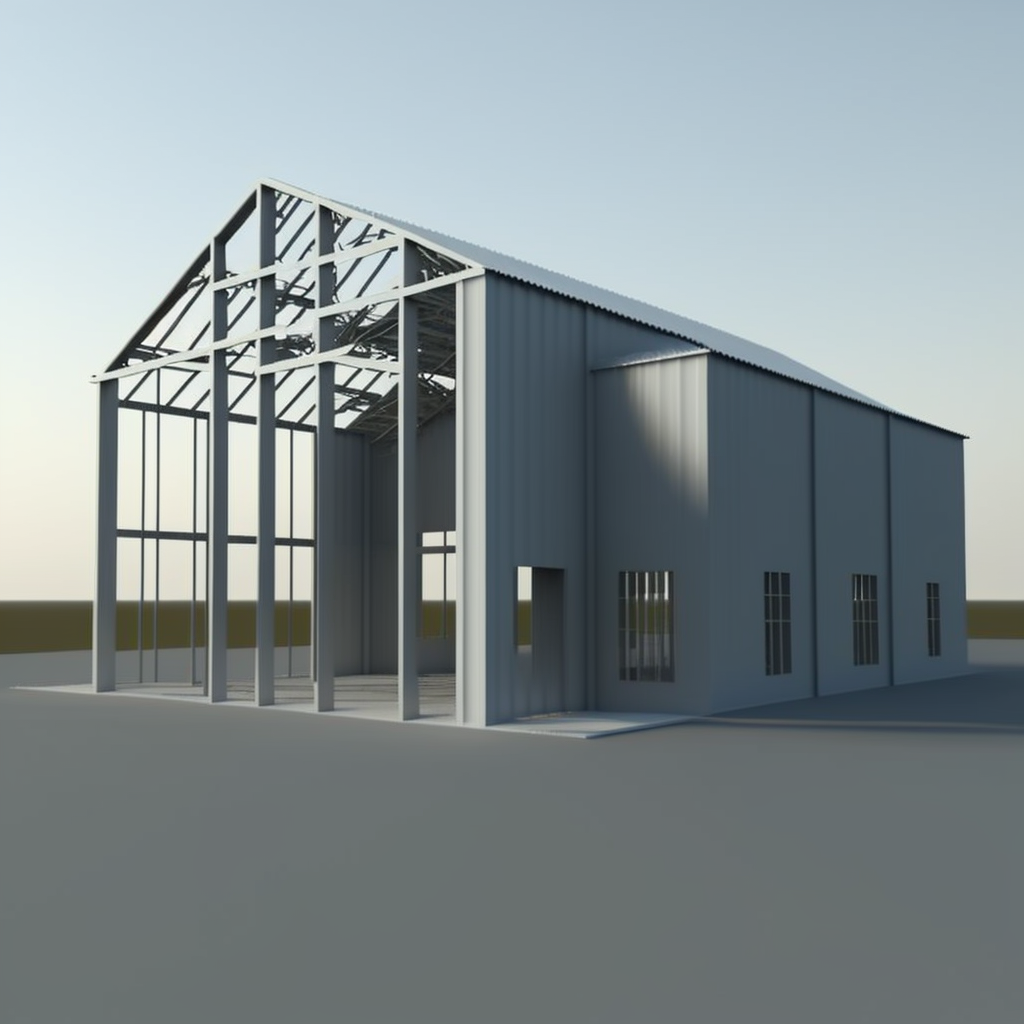

Shop drawings can be prepared based on general project designs saved in any file format or printed. Their preparation is outsourced where the supplier does not have the necessary skills, software, or resource, which is why collaboration is key in the creation process. While the Shop drawings depict the building's original design, the construction drawings are updated from time to time. They include the revisions a building has completed while the construction process is happening. One of the basic characteristics of Shop drawings is that they are not limited to the building's exterior structure. They are also helpful in identifying what kind of materials will be required for the construction process.

Every building project requires a unique approach for its realisation, which is possible through the precision and reliability of shop drawings.

The software tools today are extremely efficient, accomplish tasks quickly, and retrieve data easily. Tasks no longer depend on the limitations of office use. The drawings can be observed using various technology devices. Advice, suggestions, and changes can be made and tracked in a short time while allowing all stakeholders to follow up with revisions and updates.

The shop drawings can also be submitted electronically. The experience of preparing a complete set of shop drawings allows professionals to reflect on cost and constructibility issues as inevitable parts of the project.

The benefits of shop drawings

The accuracy and precision of shop drawings are vital to the success or failure of an engineering project. The contractor is responsible for their creation and must review the shop drawings before transferring them to the architect and engineer. The architects and engineers should not review any shop drawing unless the contractor has reviewed it first. With the advancement of computer-aided drafting and 3D modelling technologies (such as Tekla and Inventor) and electronic submittals and review processes, innovative steps have been made to improve the shop drawing process. Long term, when all the parties involved in the process can share their data and their 3D models so they can work off the same database, it can immensely improve the shop drawings' accuracy and quality.

RECENT NEWS POSTS

TESTIMONIALS

“We have been fortunate to work with National Steel Detailing on multiple projects in the past 4 years. Some really challenging builds have been made easier due to the knowledge, experience and engineering details from National Steel Detailing. We look forward to continuing working together”

MATT CHAPMAN, MATTBUILD

“National Steel have handled a wide variety of projects for us over the last 6 months, they have made the detailing of projects seamless as as stress free as possible. Their expertise, patience, and advice are very much appreciated. It is a pleasure doing business with Nick and I wouldn’t hesitate to recommend him.”